SHEET METAL CUTTING & FORMING

Our sheet metal cutting and forming services are built for precision, efficiency, and repeatability. Whether you're working with mild steel, stainless steel, or aluminium, we deliver clean, accurate cuts and consistent forms to meet your exact specifications.

From simple bends and folds to complex multi-stage forms, our machines and experienced operators handle every detail with care. We work with a wide range of thicknesses and profiles — producing everything from ductwork and brackets to custom panels, trays, and covers. Whether you need a one-off piece or batch production, we ensure tight tolerances and a smooth finish every time.

Customers choose us because we combine precision machinery with hands-on expertise. We don’t just cut and fold — we understand what your project needs to function and fit. From accurate dimensions to clean bends and consistent results, we deliver high-quality sheet metal parts that are ready to use, every time.

Fast turnaround, expert advice, and nationwide delivery make us the go-to partner for reliable sheet metal solutions.

TYPES OF SHEET METAL CUTTING

SHEARING

A straight-line cutting method using a blade to slice sheet metal. It’s fast and efficient for rectangular cuts without producing chips or waste.

Best for:

Straight edges and square blanks

High-speed, high-volume jobs

Thin to medium-thickness sheets

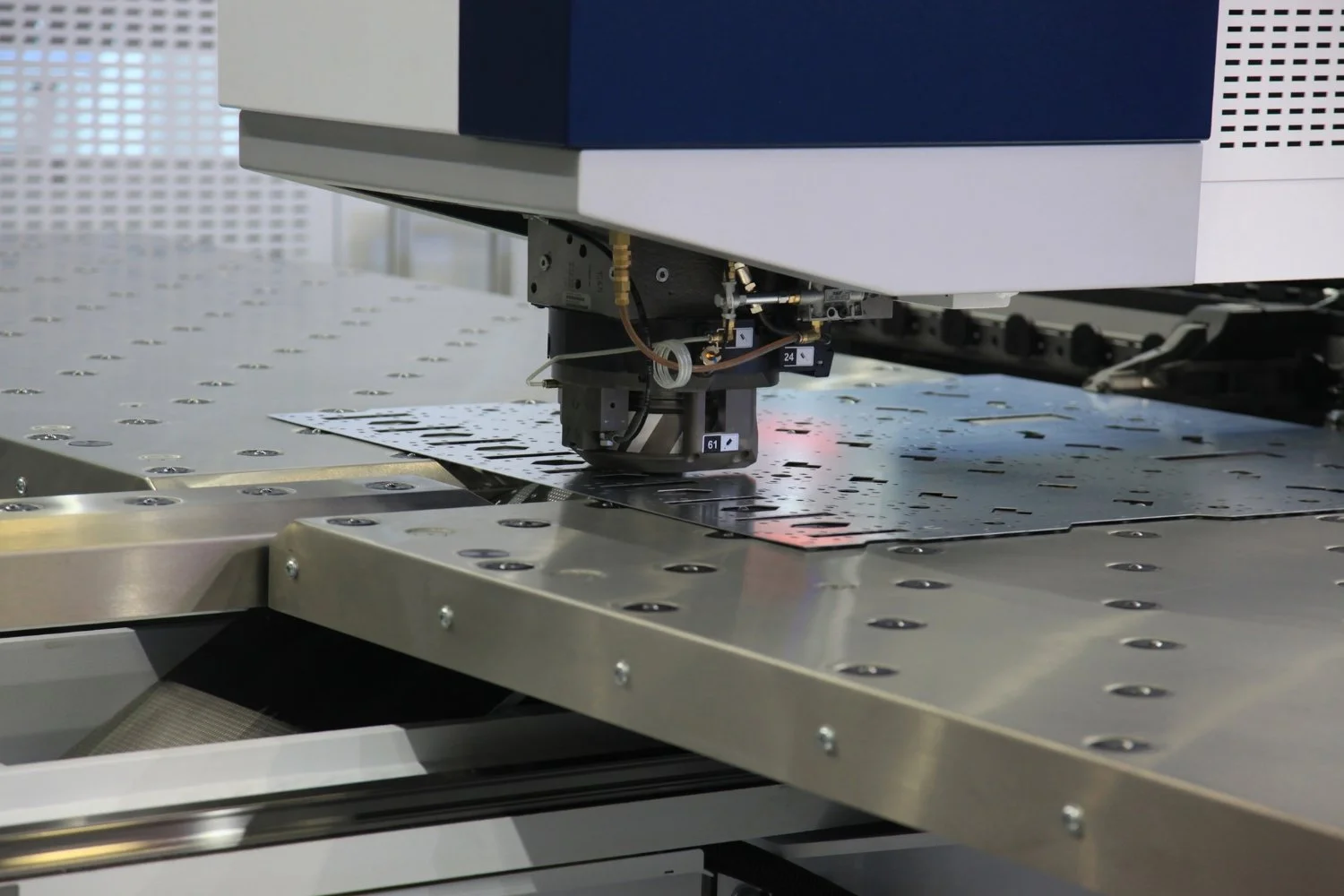

LASER CUTTING

Uses a concentrated laser beam to make precise cuts with fine detail and tight tolerances. Produces clean edges with minimal burring.

Best for:

Intricate shapes and internal cut-outs

Thin to medium sheets

High-precision applications

Sheet metal cutting is a core part of modern fabrication — and the method you choose can impact everything from edge quality to production speed. At MetalPlasmaCutting.co.uk, we offer a range of cutting techniques suited to different materials, thicknesses, and project requirements. Whether you need fast plasma cutting for heavy-duty jobs or fine-detail laser cutting, we have the tools and expertise to deliver clean, accurate results every time.

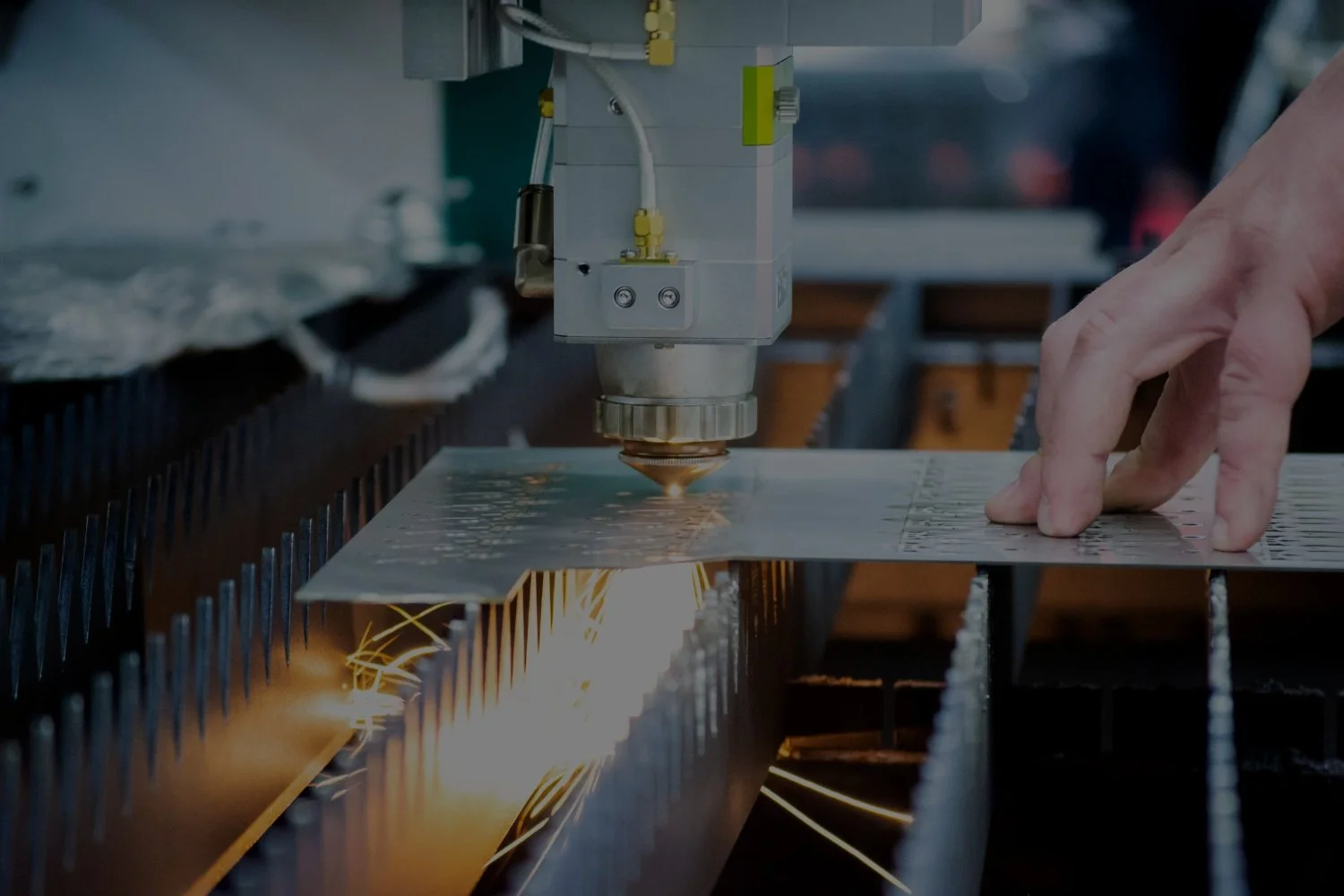

PLASMA CUTTING

Uses a high-temperature plasma arc to cut through conductive metals like steel, stainless steel, and aluminium. Ideal for thick materials and fast turnaround with minimal distortion.

Best for:

Thick sheet or plate

Fast cutting of structural parts

Clean cuts in conductive metals

EXPLORE OUR METAL FORMING SERVICES

PERFECT FOR:

-

Architectural and Structural Metalwork

We supply accurately cut and formed sheet metal for a wide range of architectural and structural applications. Whether it’s decorative panels, custom trims, cladding, or structural brackets, our work is trusted by contractors, builders, and fabricators across the UK. Our precision ensures that everything fits as it should — saving time on-site and reducing installation costs. With materials like stainless steel and aluminium, we also offer corrosion-resistant options for both indoor and outdoor use.

-

Electrical Enclosures and Control Panels

Our CNC sheet metal cutting and forming services are commonly used to produce custom electrical enclosures, control boxes, and switch panels. We work from your drawings to create accurately sized boxes with pre-cut holes, bends, and fastener positions — ensuring quick and easy component integration. Whether it’s a small housing or a large multi-compartment enclosure, we deliver high-quality, ready-to-assemble parts with tight tolerances and smooth finishes.

-

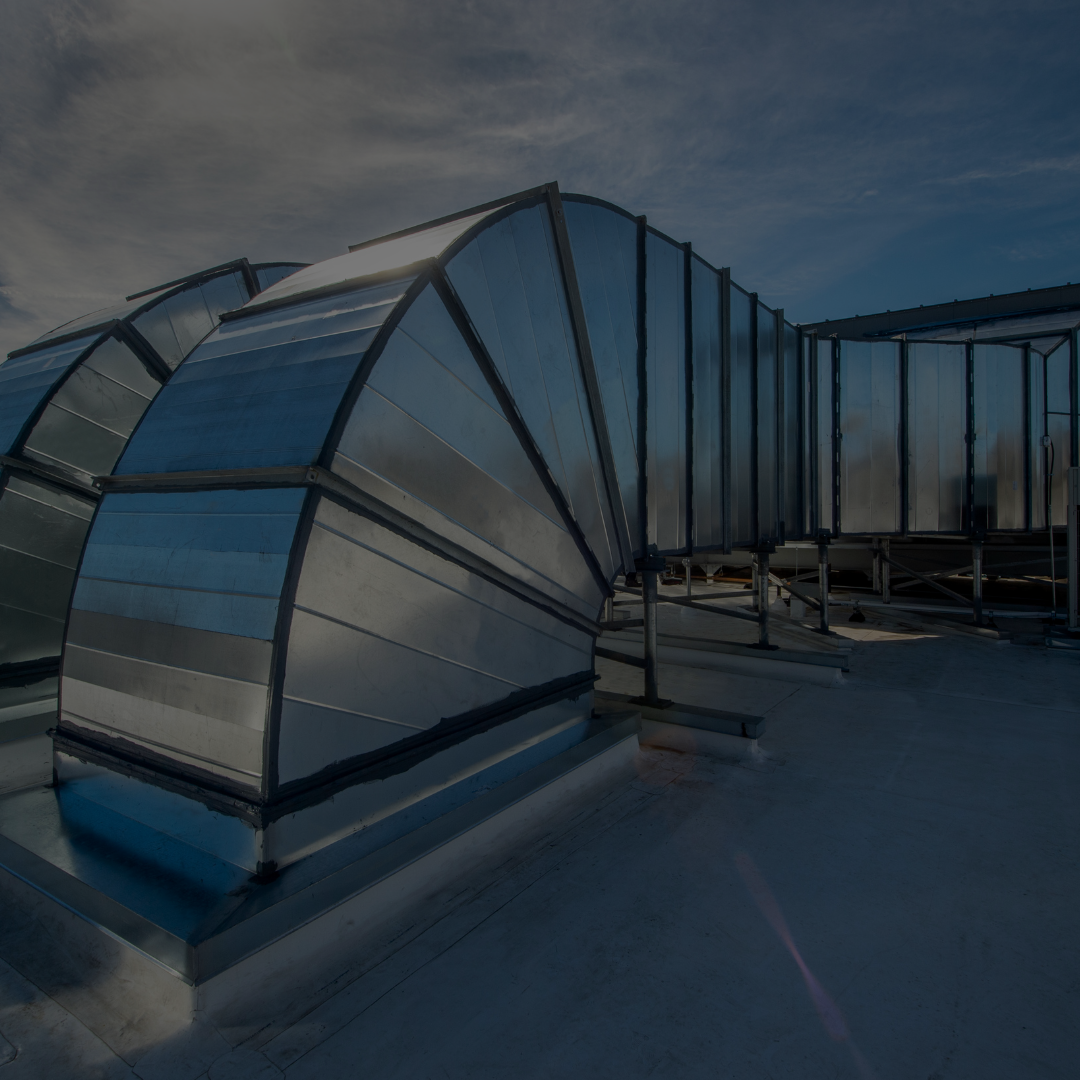

HVAC Components, Trays, and Folded Brackets

We manufacture custom sheet metal trays, brackets, ducting components, and support frames tailored to HVAC systems. From basic mounting brackets to fully formed trays and airflow panels, our service supports both commercial installations and bespoke builds. Our forming capabilities ensure smooth bends, accurate folds, and consistent profiles — perfect for ensuring efficient airflow and strong mechanical support in ventilation and cooling systems.

BUILT TO FIT, BUILT TO LAST

TYPES OF SHEET METAL FORMING

Sheet metal forming is the process of shaping flat metal into functional components through controlled deformation — without removing material. From clean bends and precise folds to curved profiles and punched patterns, each forming method offers unique advantages depending on the part's purpose and design. Below are the most common types of sheet metal forming used across manufacturing, construction, and fabrication industries.

ROLL FORMING

A continuous bending process using rollers to shape sheet metal over long lengths. Great for uniform profiles and high-volume jobs.

Best for:

Long, consistent parts (e.g. rails, channels)

Mass production

Lightweight materials

PUNCHING

Uses a punch and die to create holes, slots, or complex patterns in sheet metal. Often part of a larger forming or assembly process.

Best for:

Mounting holes

Perforated sheets

Tabs, notches, and patterns

BENDING

The most common forming method. Uses a press brake to create V-shaped, U-shaped, or custom angles in sheet metal.

Best for:

Brackets, panels, and enclosures

Simple folds and precise angles

Thin to medium materials

TRUSTED FOR OUR PRECISION, SPEED, AND NO-FUSS SERVICE — WE GET THE JOB DONE RIGHT, FIRST TIME.

FAQs

-

We work with a wide range of metals including mild steel, stainless steel, aluminium, and galvanized steel. If you have a specific material in mind, just ask.

-

We typically cut and form sheet metal from 0.5mm up to 25mm thick, depending on the material and the project. Let us know your requirements and we’ll advise accordingly.

-

Yes — we support everything from single custom fabrications to large-scale production runs, all with consistent quality and fast turnaround.

-

We use press brake bending, rolling, and folding techniques to shape metal into precise angles, curves, and custom profiles depending on your project needs.

-

If you have one, great — we accept most file formats including DXF and DWG. If not, we offer CAD design services to bring your idea to life.

-

Our equipment and experienced team deliver consistently tight tolerances for both cutting and forming — ensuring parts that fit first time, every time.

-

Turnaround varies based on job size and complexity, but we offer fast lead times and priority options for urgent jobs. Get in touch for a tailored quote.

-

While we focus on cutting and forming, we work with trusted partners to offer finishing services such as powder coating, galvanising, and painting upon request.

-

Yes — using plasma or laser cutting, we can handle detailed cut-outs, slots, and custom profiles to your exact specifications.

-

Absolutely. We offer nationwide delivery with secure packaging to ensure your parts arrive in perfect condition, ready for installation.

CONSISTENT RESULTS. EVERY CUT. EVERY FOLD.

CONTACT US

sales@actuationvalve.com

0151 547 1221

Need a custom metal part cut with precision? Whether it’s a one-off component or a full production batch, our plasma cutting specialists are ready to help.

Send us your project details using the form, and we’ll get back to you quickly with a quote or the next steps.