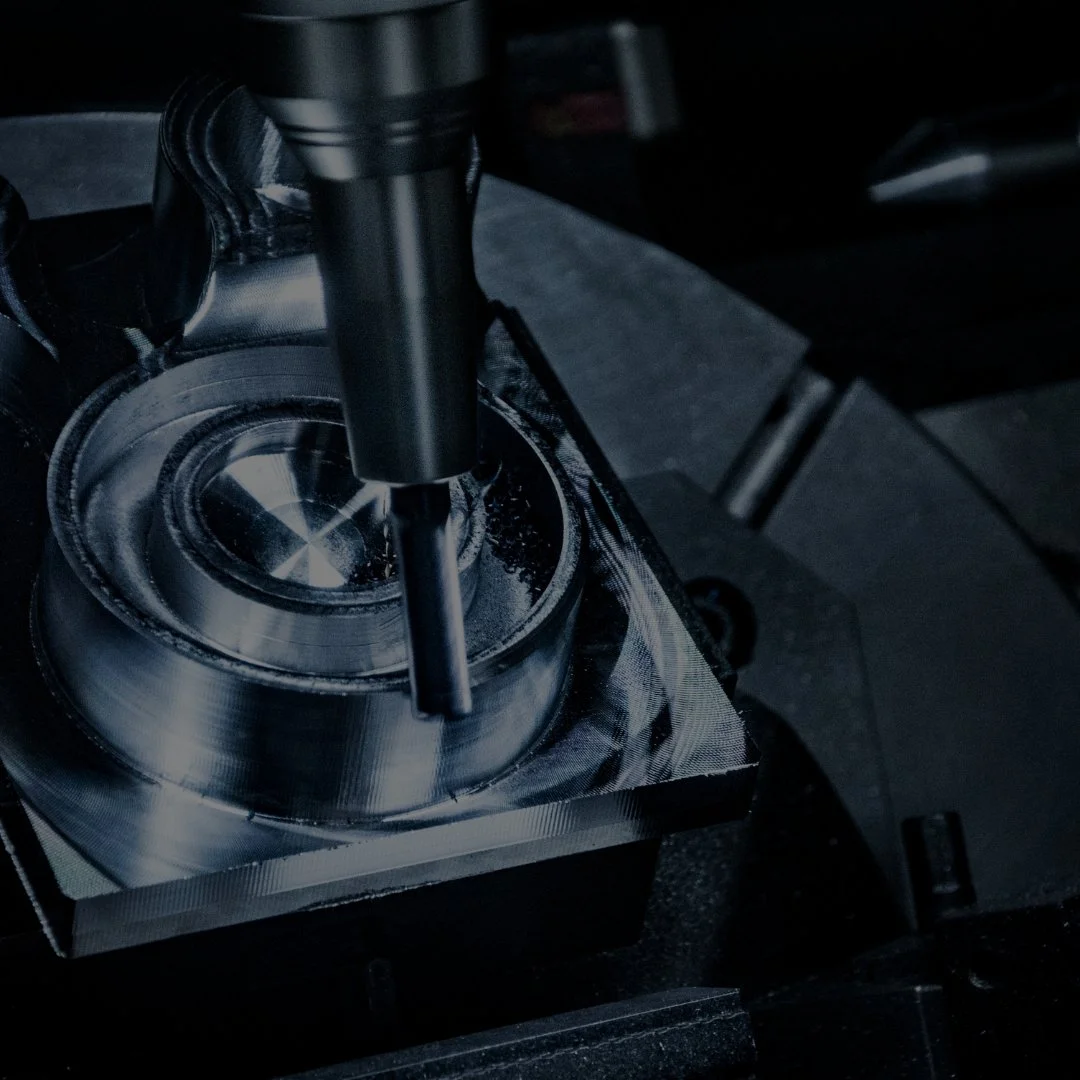

CNC MACHINING SERVICES

We offer expert CNC machining services from our unit in Liverpool, designed for precision, repeatability, and fast turnaround. Whether you're producing a single prototype or a full production run, our CNC milling and turning capabilities ensure every part is made to exacting standards. We work with a wide range of materials including mild steel, stainless steel, aluminium, and more.

Our experienced team uses advanced CNC machinery to handle both simple and complex geometries with ease. From industrial brackets to intricate mechanical components, we deliver consistent accuracy and smooth finishes every time — no compromises.

We serve a wide range of industries including construction, fabrication, engineering, and manufacturing. Our CNC machining services are ideal for parts that demand tight tolerances, long-term durability, and professional-grade performance.

We can work from your existing CAD files or help develop your designs in-house with our CAD/CAM support. Every job is quoted quickly, machined efficiently, and quality checked before dispatch — giving you peace of mind from start to finish.

-

Tight Tolerances

Our CNC machining service is built for projects that demand absolute accuracy. Whether you're producing parts for industrial machinery, custom tooling, or structural components, we achieve tight tolerances that meet even the most stringent engineering requirements. Every cut, edge, and bore is precision-controlled — ensuring a perfect fit and finish with every order.

-

Milling & Turning

We offer both CNC milling and turning to provide complete flexibility in component manufacturing. From flat-surfaced brackets and plates to cylindrical shafts and threaded parts, our equipment can handle it all. By combining both services under one roof, we streamline the production process and reduce lead times — delivering reliable, high-quality parts at scale.

-

Material Flexibility

Our CNC machines are capable of handling a wide variety of materials, including mild steel, stainless steel, aluminium, brass, and engineering plastics. No matter the material or application, we apply the same level of precision and control to every job. This allows us to cater to industries ranging from general fabrication to automotive and aerospace.

-

Prototype to Production

Whether you need a one-off prototype or a full production run, our CNC machining capabilities scale to meet your needs. We support everything from rapid prototyping for design validation to high-volume manufacturing for established parts. With fast turnaround and consistent output, we’re the ideal machining partner from first draft to final delivery.

EXPLORE OUR CNC METAL CUTTING SERVICES.

CNC TURNING (LATHE MACHINING)

CNC turning, also known as lathe machining, is used to create rotational parts by spinning a workpiece against a stationary cutting tool. The tool gradually removes material while the part rotates, making it ideal for manufacturing perfectly round, cylindrical, or symmetrical shapes with tight tolerances.

This process is extremely efficient for high-speed, high-accuracy production of mechanical components. Our CNC lathes can handle various materials — including steel, aluminium, and brass — and are perfect for creating detailed grooves, tapers, threads, and chamfers.

Common applications include:

• Shafts for motors and pumps

• Precision pins and rollers

• Custom threaded fittings and connectors

CNC DRILLING

CNC drilling automates the process of creating precision holes in metal and other materials, maintaining consistent placement, diameter, and depth across every part. Drilling is often integrated into a broader CNC workflow, complementing milling and turning operations to produce finished parts that are assembly-ready.

Our machines can drill holes for fasteners, alignment pins, mounting points, and more — with the ability to countersink, counterbore, or tap holes to your exact specifications.

Common applications include:

• Bolt hole patterns in structural or mechanical plates

• Brackets and flanges with consistent mounting points

• Threaded holes for fasteners and assemblies

CNC GRINDING

CNC grinding is a specialist machining method used to achieve exceptionally smooth surface finishes and highly accurate dimensions — especially in hardened metals. Using a high-speed abrasive wheel, material is ground away in fine layers, making this process perfect for tools and parts that must meet extremely tight tolerances.

It’s often used in final-stage finishing or where cutting methods alone can’t deliver the required surface quality. CNC grinding ensures precision while eliminating surface imperfections that could affect performance.

Common applications include:

• Sharpening cutting tools and dies

• Finishing hardened shafts or rollers

• High-precision molds and stamping dies

CNC ROUTING

CNC routing is a high-speed machining process ideal for cutting, shaping, and engraving softer materials such as plastics, composite panels, and lightweight metals like aluminium. CNC routers operate similarly to mills but at faster speeds, making them especially effective for detailed or decorative cuts in flat sheet materials.

With fast cycle times and exceptional repeatability, our CNC routing services are perfect for producing complex shapes and lightweight components — all while maintaining clean edges and professional results.

Common applications include:

• Custom signage and display panels

• Lightweight plastic housings and covers

• Shaped composite sheets for enclosures or panels

FAQs

-

CNC machining is a manufacturing process where computer-controlled tools precisely cut, drill, or shape materials like metal or plastic. It ensures high accuracy, repeatability, and efficiency for both simple and complex parts.

-

We work with a wide range of materials including mild steel, stainless steel, aluminium, brass, and industrial plastics. If you have a specific material in mind, just let us know.

-

CNC milling removes material using a rotating cutting tool, ideal for flat or contoured surfaces. CNC turning spins the material while a fixed tool shapes it — best for round or cylindrical parts like shafts and bushings.

-

We can machine to tight tolerances depending on your project requirements — often within ±0.01mm. Let us know your specs, and we’ll deliver accordingly.

-

If you have one, great. But if not, we offer in-house CAD design and file conversion to create the necessary drawings from your sketches or ideas.

-

Absolutely. We support single custom parts, short production runs, and high-volume manufacturing — all with the same precision and care.

-

Lead times vary depending on complexity, quantity, and material availability. We typically turn around jobs in a few days, and we also offer express services.

-

Our CNC machines can handle small intricate components and larger industrial pieces. Share your project specs, and we’ll confirm compatibility.

-

While CNC machining can have a higher upfront cost than manual methods, it offers better consistency, speed, and reduced waste — saving money over time, especially on repeat jobs.

-

Yes, we ship all over the UK. Once your parts are machined and quality-checked, we’ll dispatch them safely and quickly to your address.

TRUSTED FOR OUR PRECISION, SPEED, AND NO-FUSS SERVICE — WE GET THE JOB DONE RIGHT, FIRST TIME.

CONTACT US

sales@actuationvalve.com

0151 547 1221

Need a custom metal part cut with precision? Whether it’s a one-off component or a full production batch, our plasma cutting specialists are ready to help.

Send us your project details using the form, and we’ll get back to you quickly with a quote or the next steps.