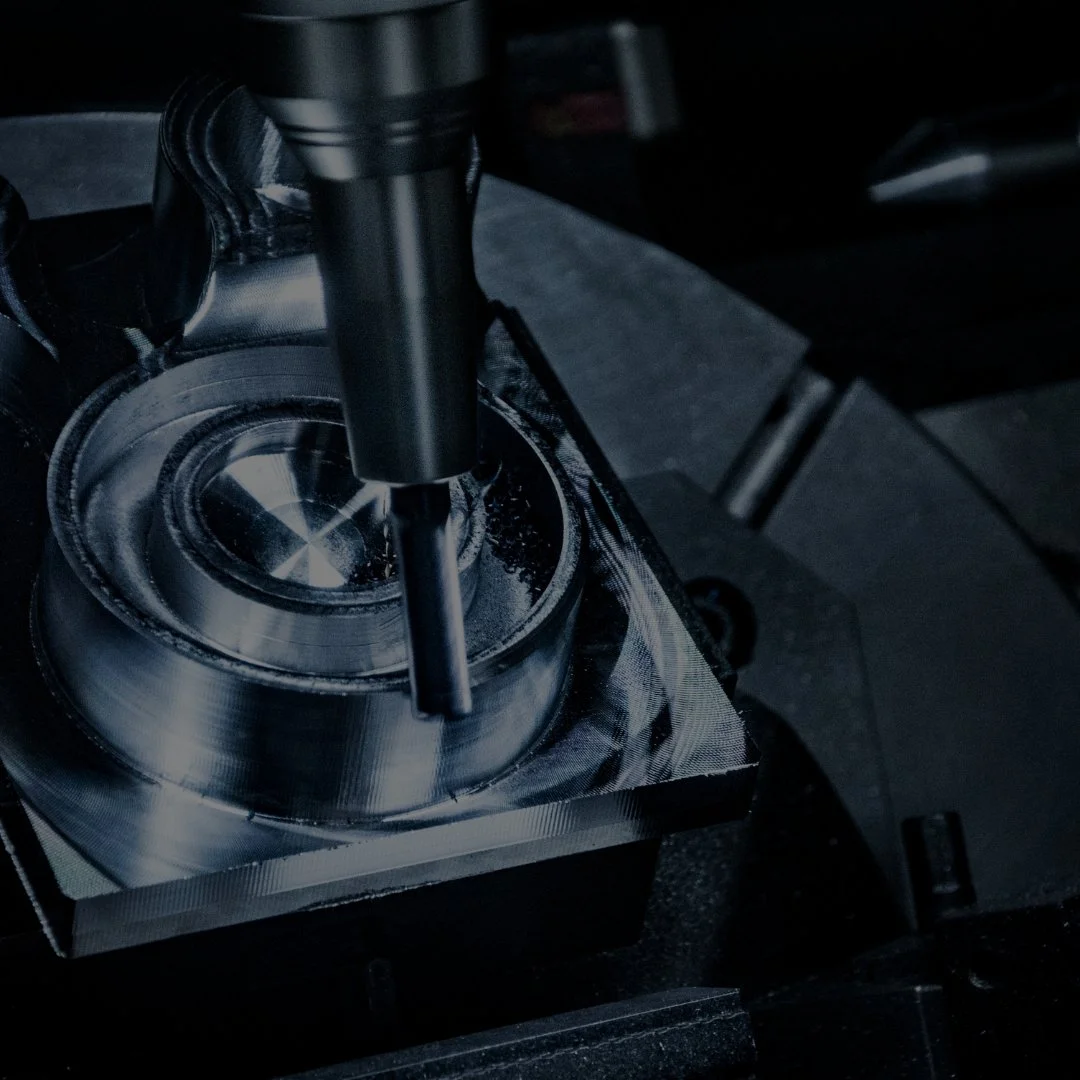

CNC TURNING

HIGH PRECISION LATHE MACHINING FOR SHAFTS, BUSHINGS & CUSTOM CYLINDRICAL COMPONENTS.

At MetalPlasmaCutting.co.uk, we provide expert CNC turning services for customers across the UK, delivering reliable, repeatable, and high-precision components for a wide range of industrial and commercial applications.

Whether you're producing one-off prototypes or large-volume runs, our CNC lathe capabilities allow us to machine cylindrical and symmetrical parts with exceptional consistency and accuracy.

CNC turning is ideal for producing round metal components such as shafts, rods, pins, sleeves, and threaded parts. Using computer-controlled lathe systems, we rotate the material at high speeds while fixed cutting tools shape it into your required dimensions. This method offers high efficiency, reduced material waste, and ultra-tight tolerances — making our CNC turning services the preferred choice for industries that demand performance and precision.

What Makes Our CNC Turning

Services Stand Out?

Our in-house CNC turning machines are equipped to handle various metals including mild steel, stainless steel, aluminium, brass, and engineering-grade alloys. With fast cycle times and consistent quality control, we deliver ready-to-use parts for customers across sectors like manufacturing, construction, automotive, and machine building.

We support:

Bar stock and round blanks

External and internal threading

Tapered cuts, grooves, and undercuts

High surface finish quality

Small and large batch runs

Whether you're machining a few custom parts or need ongoing production supply, our CNC turning services ensure maximum efficiency without compromising quality.

APPLICATIONS

-

Shafts & Axles

We manufacture precision-machined shafts and axles for a variety of applications, including electric motors, gearboxes, and mechanical drive systems.

Using CNC turning, we achieve exceptional roundness, balance, and concentricity — which is critical for reducing wear and vibration during operation. Whether you need a custom-length shaft, stepped diameter, keyways, or chamfered ends, we can deliver consistently machined components to exact specifications.

-

Threaded Components

Our CNC turning services are widely used for producing internally and externally threaded components, including custom bolts, adaptors, couplings, and precision fasteners.

We support both metric and imperial threads, and can create fine or coarse thread profiles as required. Threads are cut cleanly and to the correct pitch and depth using controlled lathe tooling — ensuring a snug, secure fit and compatibility with other mechanical parts.

-

Pins, Bushings & Spacers

We produce custom pins, bushings, and spacers with tight dimensional tolerances and smooth surface finishes — essential for applications requiring reliable alignment, movement, or load-bearing support.

Our CNC turning process ensures consistent outer diameters, precise lengths, and optional features like chamfers, grooves, or tapers.

-

Custom OEM Components

For original equipment manufacturers, we offer complete custom CNC turning services tailored to your production and prototyping needs.

Whether you're building a one-off machine or scaling up for batch manufacturing, we can produce turned components such as bearing housings, collars, rotating shafts, bushings, and enclosure parts.

“We needed a batch of precision-turned components on a tight deadline, and the team absolutely delivered. The quality was spot on, with every piece matching spec perfectly. Communication was great throughout, and they even helped us tweak our design for better efficiency. Can’t recommend them enough for CNC turning work!”

— Mark D., Operations Manager,

CONTACT US

sales@actuationvalve.com

0151 547 1221

Need a custom metal part cut with precision? Whether it’s a one-off component or a full production batch, our plasma cutting specialists are ready to help.

Send us your project details using the form, and we’ll get back to you quickly with a quote or the next steps.