CASE STUDIES - ARCHITECTURAL FABRICATION

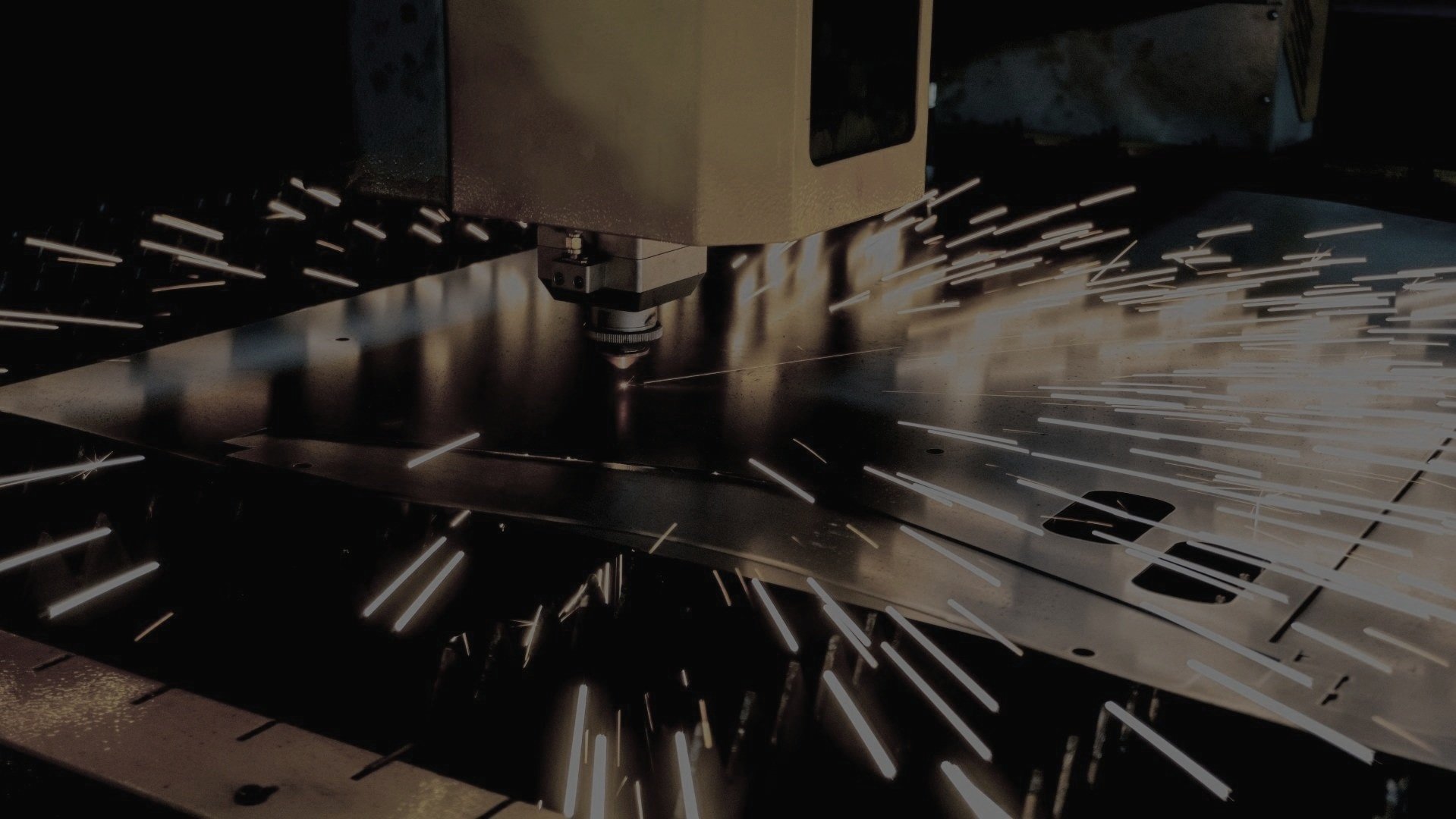

We were approached by a UK-based architectural fabrication company in need of high-precision metal components for a bespoke design installation.

The project required a series of plasma-cut panels and brackets with intricate detailing, tight tolerances, and a clean finish suitable for a visible architectural feature.

HOW DID WE DO IT?

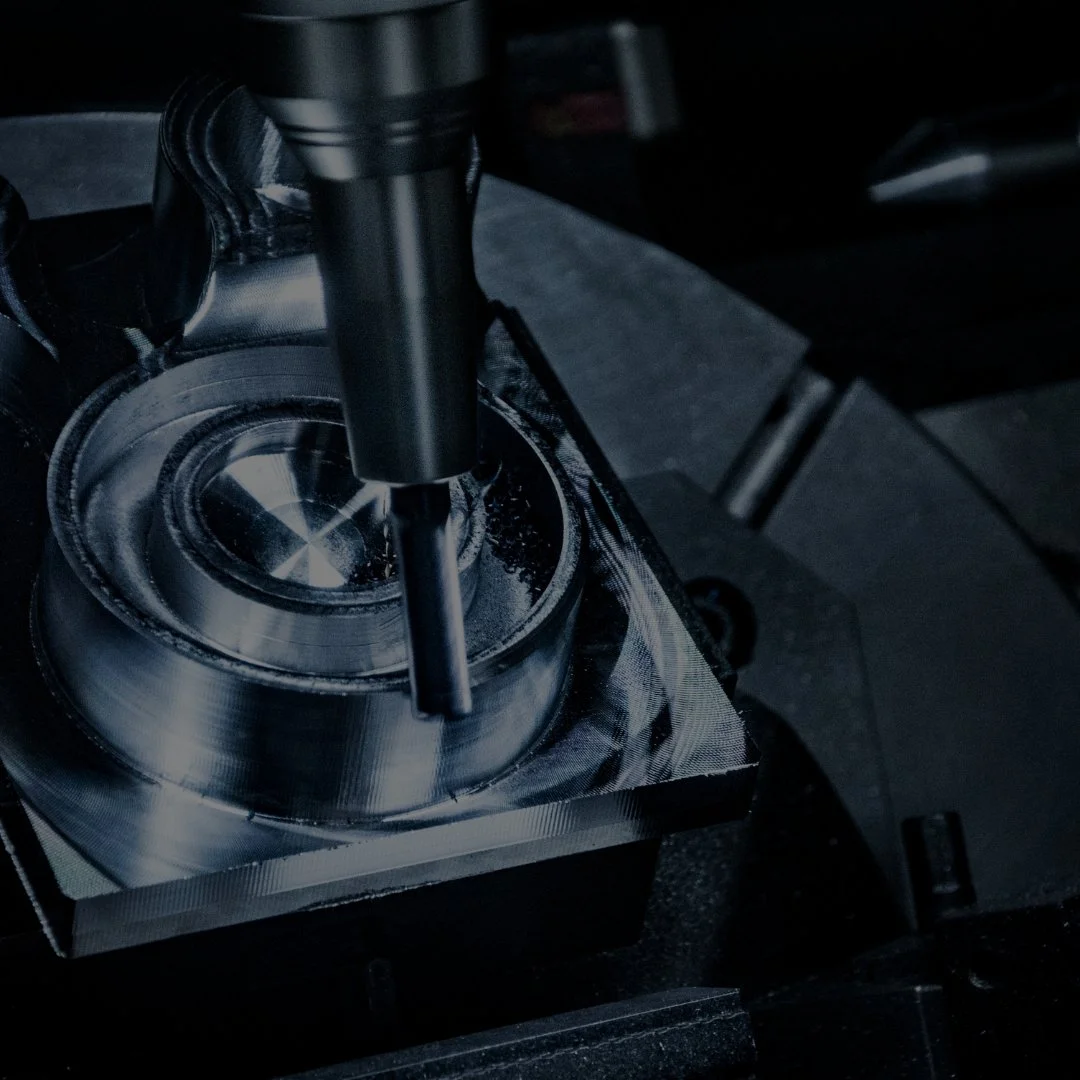

Using our advanced CNC plasma cutting technology, we produced a full set of components to exact design specifications, ensuring perfect alignment during assembly and installation.

The result was a seamless integration of form and function — helping our client deliver a striking final build with confidence in the structural integrity of every piece.

Project Highlights

-

Intricate Detailing

Clean, precise cuts for visible architectural use.

-

High Accuracy

CNC plasma cut to tight tolerances for perfect fit.

-

Design Compatibility

Produced directly from client CAD drawings.

-

Material Quality

High-grade steel and aluminium panels as specified.

CLIENT FEEDBACK

"We needed precision and reliability for a high-visibility project — and Metal Plasma Cutting delivered on both. The components arrived exactly as drawn, with a flawless finish and fast turnaround. Couldn’t have asked for more."

— Lead Fabricator, Architectural Client

Got something similar in mind?

From one-off design features to larger structural packages, we can cut to suit your project needs.

Send us your drawings or details, and we’ll get back to you with a tailored quote or next steps.

Unit C, Beckett Close, Centro Park,

Knowsley Industrial Park,

L33 7XS

HOURS

Monday–Friday

8am–5pm

PHONE

0151 547 1221

CONTACT US

sales@actuationvalve.com

0151 547 1221

Need a precision-cut metal part? Whether you’re after a single custom piece or a full production run, our plasma cutting team is ready to deliver.

Send over your project details using the form, and we’ll respond quickly with a quote or guidance on the next steps.