What Is the Metal Cutting Process?

The metal cutting process is a fundamental manufacturing technique used to shape, size, and finish metal components through the removal of material. Whether producing intricate aerospace parts, structural steel for construction, or precision-engineered machinery, metal cutting plays a crucial role in achieving accuracy, surface finish, and performance standards across industries.

In simple terms, the metal cutting process involves using tools or machines to remove unwanted material from a workpiece to achieve a desired geometry. This can be done through mechanical, thermal, or chemical means depending on the material type, required precision, and production scale. At MetalPlasmaCutting.co.uk, our advanced machinery and expertise allow us to offer high-quality cutting solutions tailored to each client’s needs — from mild steel to stainless, aluminium, and exotic alloys.

Types of Metal Cutting Processes

There are several main types of metal cutting processes, each with its own benefits and best-use scenarios:

1. Mechanical Cutting

Mechanical methods rely on physical force to remove material. This includes sawing, shearing, drilling, turning, and milling. These processes are ideal for precise shapes and repeatable production, especially in small to medium-scale manufacturing.

2. Thermal Cutting

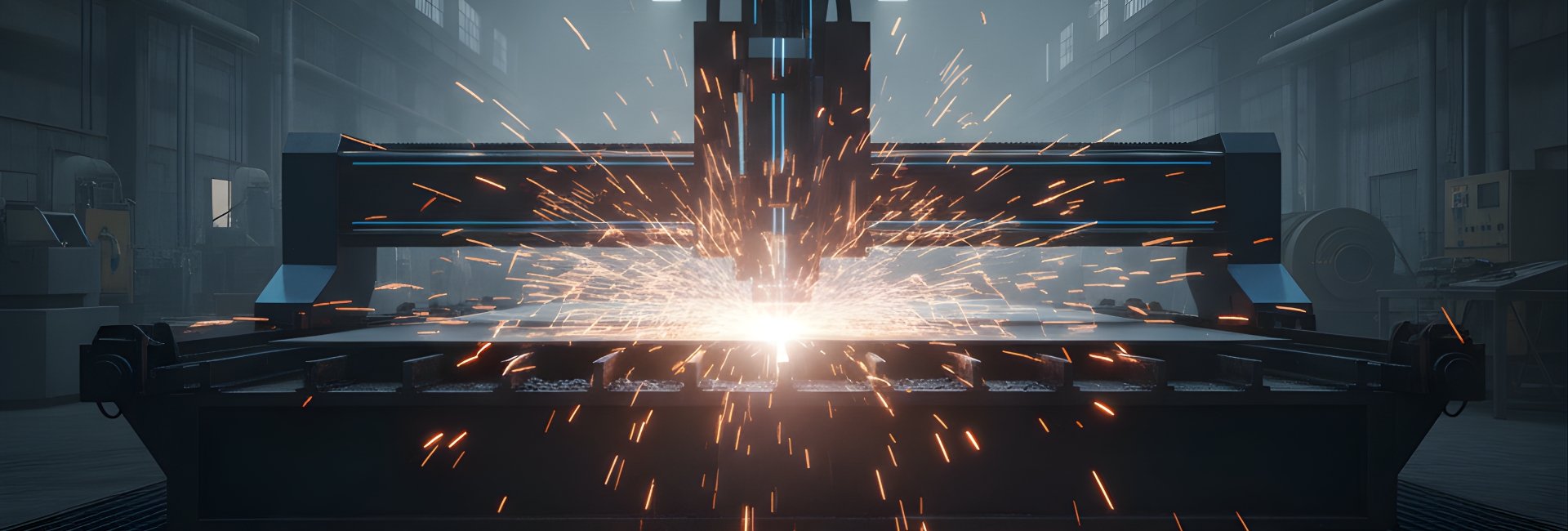

Thermal cutting uses heat energy to melt or vaporise the material at the cut line. Popular thermal cutting techniques include:

Plasma Cutting: Uses an ionised gas jet (plasma) to melt through metal with incredible precision. Perfect for stainless steel, aluminium, and conductive metals.

Laser Cutting: Delivers an extremely fine and accurate cut using concentrated light beams. Excellent for thin sheets and intricate designs.

Oxy-Fuel Cutting: Uses oxygen and fuel gas to cut thick sections of carbon steel — ideal for heavy-duty industrial fabrication.

At Metal Plasma Cutting, we specialise in plasma cutting, offering high-speed, accurate cuts with minimal heat distortion — perfect for demanding engineering applications.

3. Electrical and Chemical Cutting

Advanced methods such as Electrical Discharge Machining (EDM) and Electrochemical Machining (ECM) are used when ultra-precision is required. These processes are often employed in aerospace, medical, and micro-engineering industries where tolerances are extremely tight.

Stages of the Metal Cutting Process

The metal cutting process typically involves the following key stages:

Material Selection: Choosing the appropriate metal based on mechanical strength, corrosion resistance, and application.

Design and Programming: CAD drawings and CAM software guide the cutting path, ensuring efficiency and accuracy.

Setup and Fixturing: The workpiece is secured, and cutting parameters such as feed rate, current, and gas pressure are set.

Cutting Operation: The selected method (e.g. plasma, laser, or mechanical) removes material according to the design.

Finishing: Post-processing steps like deburring, polishing, or coating enhance appearance and durability.

Each stage requires precision and attention to detail to achieve the perfect final result — something we take pride in at MetalPlasmaCutting.co.uk.

Benefits of the Metal Cutting Process

Precision and Accuracy: Achieve exact dimensions and tight tolerances.

Smooth Edge Quality: Modern cutting methods produce clean, burr-free edges.

Versatility: Works on a wide range of metals — from carbon steel to aluminium and titanium.

Efficiency: Advanced plasma and laser systems deliver faster turnaround times.

Cost-Effectiveness: Reduces waste and eliminates the need for extensive machining.

Applications of Metal Cutting

The metal cutting process is used across countless industries, including:

Construction: Beams, panels, and brackets.

Automotive: Exhausts, chassis components, and panels.

Aerospace: Lightweight precision parts.

Manufacturing: Custom machinery and fabricated components.

Art and Design: Decorative metal panels, signage, and sculpture work.

Whatever your project requires, Metal Plasma Cutting has the capability and expertise to deliver.

FAQs About the Metal Cutting Process

1. What is the difference between plasma cutting and laser cutting?

Plasma cutting uses an ionised gas to melt metal, making it ideal for thicker materials, while laser cutting uses a focused light beam, perfect for thin and detailed work.

2. Can plasma cutting be used on all types of metal?

Yes, plasma cutting can be used on all electrically conductive metals, including steel, stainless steel, copper, aluminium, and brass.

3. How accurate is the metal cutting process?

Modern CNC-controlled plasma and laser systems can achieve tolerances within ±0.2mm, depending on the thickness and material.

4. Does the metal cutting process cause heat distortion?

Traditional thermal methods can, but advanced plasma systems like ours are designed to minimise heat-affected zones for cleaner results.

5. What information do I need to provide for a quote?

Typically, we require your CAD file or dimensions, metal type, thickness, and quantity to generate a precise quotation.

Contact Us

At MetalPlasmaCutting.co.uk, we combine technical expertise with advanced machinery to deliver high-quality metal cutting services for every project. Whether you need one-off components or large-scale fabrication, our team is ready to help.

Get in touch today to discuss your requirements and receive a free, no-obligation quotation.